Emission control areas are those designated regions at sea wherein the Sox and Nox emissions are regulated by the laws laid down under MARPOL Annex VI- Prevention of air pollution by ships.

Some local laws regarding air pollution are more stringent than those laid down by the IMO. For e.g. in Europe while the ship is at port, all the running machinery consuming fuel must use only the type of fuel having less than 0.1% sulfur content.

As the SOx emission is purely dependent on the quality and sulfur content of the fuel, while entering emission control areas, it is required to switch over to a lower sulfur content fuel including flushing of fuel from the system with sulfur content more than 1.0% sulfur before entering the ECA.

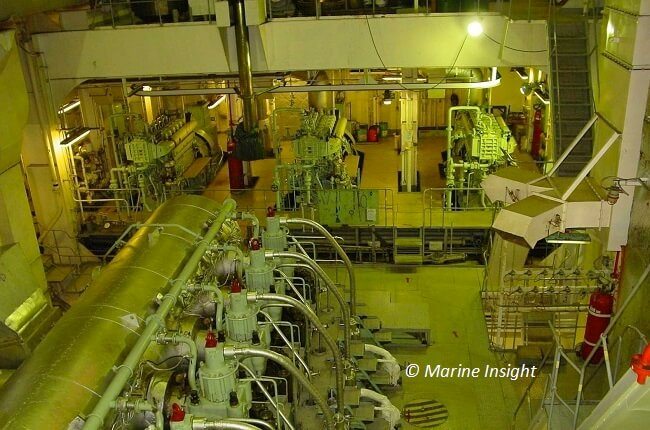

Fuel Oil Changing Over Procedure for Main Engine

Considering that most of the ships today run at high sulfur fuel oil, changing over of fuel at the right time is very important. Moreover, looking at today’s economic condition of the industry, it’s imperative to change over the fuel from high to low sulfur at correct time as an early change over will lead to loss of low sulfur oil, which is quite expensive, whereas a delay in the changeover procedure will lead to violation of MARPOL annex VI. This is to be done along with using other technologies to reduce SOx and NOx from ships.

Also most of the ships today are equipped with one service tank and one (may be two) settling tanks, which can result in mixing of two different grades of oils while performing changing-over of fuel. Needless to say changing over of fuel includes several important factors under consideration.

Every ship is provided with changeover Low Sulphur Fuel (LSF) calculator which tells the correct changeover time at which the system should be running on LSF before entering an Emission Control Area (ECA). This system requires some important factors –

- The sulfur content of high sulfur fuel currently in the system

- The sulfur content of low sulfur fuel

- The fuel capacities of the main engine system including settling tank, service tank, main engine piping and transfer piping from service tank to main engine

- Capacity of transfer equipments – Fuel oil transfer pump and fuel oil separators

Once the change-over time is calculated which also accounts the time of intermixing of two different sulfur grades oil (let’s suppose 48 hours), following action are to be taken 48 hours prior:

- Ensure that no transfer of high sulfur fuel is carried out any further to settling tank

- Ensure that the low sulfur bunker tank steam is open for transfer and purification of fuel should not have any problem

- If two separate settling tanks are present, one can be dedicated to low sulfur oil which will reduce the changeover period

- Keep running the separator till the settling tank level reaches minimum

- If filling of service tank with HSFO increases the calculated time period of changeover, then stop the separator and drain the settling tank

- Settling tank can be first drained in to fuel oil overflow tank, and then the oil drained can be transferred to bunker tanks containing same grade of oil

- Once the settling tank is drained from heavy sulfur oil, fill the settling tank with low sulfur oil via transfer pump

- As the separator are stopped, service tank oil will be consumed by main engine system

- Remember not to lower the level of service tank below which the fuel pumps cannot take suction

- Start separators from settling to service tank which will be now filling low sulfur oil

- Fill the LSFO oil in to settling and service tank as per the quantity required to cross the ECA calculated by the chief engineer as per the voyage plan

Records to Maintain

-Record all the fuel tank levels when changeover starts (48 hour prior)

-Mention date, time and position in the oil record book (ORB) when the changeover from high to low sulfur is carried out along with the quantity of low sulfur oil in settling and service tank

– Same can be recorded in the engine log book

Fuel Oil Change Over for Auxiliary Engine and Boilers

Some port have regulations of using gas oil for generators and boilers while the ship is at port (for e.g. European ports). Change over generators and boiler to diesel oil with sulfur content less than 0.1 %.

Boiler

- Shut the steam to the fuel oil heaters of boiler

- When the temperature drops below 90 degree, open the diesel oil service tank valve going to the boiler system

- Shut the heavy oil valve for boiler system slowly and observe the pressure of the supply pump

- Check flame and combustion of the boiler

- Let the heavy oil outlet be kept open and diesel oil outlet not be open for some time

- This is to ensure no heavy oil goes to diesel oil system

- When the line is flushed with Diesel Oil, open the diesel outlet valve and shut heavy oil outlet valve

Generators/ Auxiliary Engine

Generators must be changed over from one grade to another while at load as this will help in better flushing of the system.

If only one generator is being changed over, keep running another generator for emergency purpose incase something goes wrong.

- Shut the steam to the fuel oil heaters of boiler

- When the temperature drops below 90 degree, open the diesel oil service tank valve going to generator system

- Open the local diesel inlet valve and shut the heavy oil inlet valve simultaneously and slowly, by keeping an eye on the fuel pressure and changing only one generator into diesel with the help of separate diesel pump. Let the heavy oil outlet be kept open and the diesel oil outlet kept shut till the system is flushed thoroughly

- After some time open the diesel oil outlet and shut heavy oil outlet

- If the complete system is to be changed into diesel oil, open the diesel oil inlet valve to generator supply pump simultaneously closing the heavy oil inlet valve

- If the return line is provided to diesel service tank, open it after some time, simultaneously closing the heavy oil return only after the system is flushed properly

The changeover procedure must include recording of every action and onboard oil quantity as a proof of doing the job correctly.

Note: Once the changeover procedure is completed, remember to change the HMI setting of Cylinder oil lubricator system (Alpha lubrication) or changeover the cylinder oil daily tank suitable for low sulfur operation.

0 Comments